In a perfect world, businesses would keep on hand all the stock they need to respond to unpredictable fluctuations in demand as well as supply chain disruptions. However, the true cost of holding inventory must be considered when balancing stock levels.

But inventory levels need to be carefully managed because a range of costs associated with carrying and holding inventory will add to the total cost of procurement (TCP).

The double-edged sword is that if you have too much stock on hand, your storage and other inventory-related costs go up, eating into your margins. But if you have too little inventory, you run the risk of not being able to meet unexpected surges in demand, leading to unhappy customers.

In earlier posts, we described 11 key elements that add up to the total cost of procurement, including the specific costs that affect buying and purchasing, as well as the warehouse management side of things.

Now let’s look at how the costs of carrying and holding inventory add to your TCP — and what you can do to reduce and eliminate those costs.

How Storage Costs of Inventory Affect the Total Cost of Procurement

There are five main ways that inventory costs can cause your TCP to balloon out of control.

1. Inventory Storage Costs.

These costs, also known as inventory carrying costs, include not only what you pay to buy or lease warehouse space but also everything that’s needed to manage that space, such as climate control equipment, security systems, and physical equipment — from bins and pallets to forklifts and tech hardware. A study by Warehousing & Fulfillment found that in 2024, the average cost to run a warehouse in the U.S. amounted to $8.31 per square foot. This was a 6.4 percent increase compared to the average cost in 2020.

BPI helps lower the cost of our customers’ carrying inventory per square foot because we store the inventory until they need it, which is dramatically cheaper than storing goods in their yard. We carry a large trove of stock that allows our customers to take advantage of our discounted pricing and gives them quick access to inventory — so it turns over regularly and doesn’t rack up unnecessary storage costs.

Partnering with BPI for a just-in-time approach can keep your inventory leaner and dramatically reduce your storage costs. Doing so means having a close relationship with a reliable distributor who understands your needs and helps you keep your on-site inventory lower because they’ve got what you need in stock and can get it to you quickly.

In a time of supply chain disruptions, there’s a natural urge for dealers to maintain more safety stock. Even minor deviations from forecasted demand can add up to increased costs. Partnering with BPI provides the safety and resilience lumberyards need by absorbing the fluctuations in demand for you.

A good distributor will also save you money on all of the buying-side costs that affect TCP. Giving most of your business to a reliable distributor can result in the lowest TCP by reducing the time your team spends comparison shopping. It also reduces paperwork and the potential for errors and gets you the best service value.

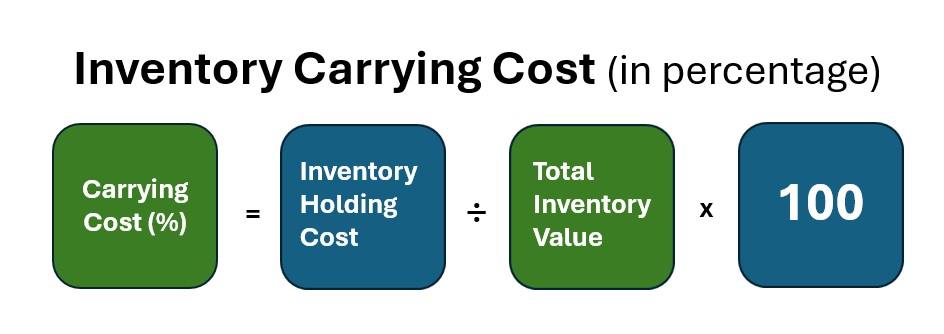

Inventory carrying costs typically represent 20%–30% of inventory value. They are calculated using this formula:

2. Inventory Financing Costs.

Maintaining a large on-site inventory can also add to your costs in terms of financing and loan maintenance fees (which may include interest). In fact, if you’re not careful, these can wind up constituting the greatest share of your carrying costs.

Adding to this impact is the risk of inventory deteriorating or depreciating over time, losing value in the process. Some items might expire; others might suffer from wear and tear during storage or go out of style, and others may get misplaced. If you buy a lot of materials cheaply but then write a lot of them off because they don’t sell, you don’t come out ahead on the deal.

Ideally, you want inventory to hit a benchmark range of 4-8 turnover cycles per year, which is considered healthy for most building materials suppliers. It’s much easier to hit that target with a dependable distributor in your corner.

3. Inventory Control Costs.

In addition to storage costs, the more inventory you keep on hand, the more carefully you need to count and monitor your supply. In order to keep a close eye on your inventory and be able to fulfill orders accurately, it’s important to embrace cycle counting.

But that brings with it increased labor costs. It means you’ll need more team members on the payroll to manage the processes of organizing and stocking materials. In addition to wages, those expenses include benefits and regular training — plus the investment in recruiting and onboarding qualified employees.

4. Inventory Shrinkage.

Keeping a large inventory on site means you also have to invest in protecting it. In addition to the risk of stock aging, expiring, or becoming obsolete, theft and clerical errors are the biggest factors that can result in a difference between the amount of stock you’re supposed to have on hand and what’s actually in your warehouse or yard.

It’s worth noting that tying up too much of your resources in inventory can cost you in terms of opportunity as well, by making your business less able to respond to market changes because of the older inventory you’ve already committed to.

5. General Inventory Overhead Costs.

Increasing your inventory can also cause taxes to balloon, from property taxes to sales taxes (which will only add to the value lost from inventory shrinkage if you don’t sell what you’ve ordered). There’s also the necessary cost of insuring your inventory against everything from natural disasters (flood, fire, tornadoes) and damage, theft, or other kinds of loss.

The bottom line is that keeping your inventory at the correct size allows you to achieve the lowest investment, which helps rein in your TCP — while also helping your business stay more maneuverable and better able to take advantage of the opportunities that lie ahead.

How BPI Can Reduce Your Inventory Costs

The good news is that BPI has designed services with precisely these issues in mind — to help lumber and building material (LBM) dealers tame inventory costs and keep them as small as possible.

Collaboration between distributors and dealers is one of the most important pillars for success in this area. A close, seasoned partnership helps both sides keep stock moving with greater visibility into the supply chain.

When stock becomes scarce, or shipments are delayed, a distributor with reps who understand your business well enough to anticipate your needs and help solve problems is an ace in your pocket. That established customer relationship also means you’ll be prioritized to receive product as soon as it becomes available.

Choosing a distributor with an excellent track record for putting customers first, coming through in a pinch, and fulfilling commitments on time strengthens your position and adds real value to your business.

As a two-step distributor, BPI’s buying power means it can pass along quantity discounts while storing the product until you actually need it—which helps save you money on all of the storage costs outlined above.

BPI Job Packs make receiving easier and more efficient by packaging related items so they arrive together, on time. This can make the turnaround to the job site faster than ever, increasing inventory turns while preventing mistakes and reducing internal handling needs.

The BPI Picture Delivery Program makes tracking orders easier by providing you with access to visual proof of delivery — which helps reduce shrinkage and mitigate theft. At the same time, BPI’s careful packaging helps protect materials to minimize damage — both during delivery and on the job site.

Did you miss the first two posts? Catch up here:

Get in touch with us to find out how BPI can help your lumberyard or specialty dealership reduce costs and increase margins.