Does managing stock levels feel like a balancing act? Most lumberyards want to minimize expenses by limiting excess inventory, but also need to have enough safety stock to ensure that they can weather any unexpected changes in demand. And the wild swings in the supply chain the past few years demonstrate how important it is not to run too lean.

Does managing stock levels feel like a balancing act? Most lumberyards want to minimize expenses by limiting excess inventory, but also need to have enough safety stock to ensure that they can weather any unexpected changes in demand. And the wild swings in the supply chain the past few years demonstrate how important it is not to run too lean.

So – how do you find the right balance? In this blog, learns tips on balancing just-in-time and safety stock to help your lumberyard remain resilient amid an inconsistent supply chain.

Just-in-Time vs Safety Stock: Which Is Best?

Just-in-time (JIT) inventory management is the practice of carrying only enough inventory on hand to meet demands. The goal of this inventory management process is to minimize waste and maximize efficiency.

Distribution industry expert Jason Bader states that while many organizations run on the conventional wisdom of lean inventory and driving inventory turns, these practices are severely challenged during disruptions to the supply flow and should be re-examined.

At its core, JIT inventory is an economical and efficient way of doing business. When optimized, a JIT strategy requires partnerships with reliable suppliers to ensure products are available when they are needed. The problem is that JIT relies on a steady supply chain, and if we’ve learned anything from 2020, it’s that a consistently stable supply chain is nearly impossible in an unstable world.

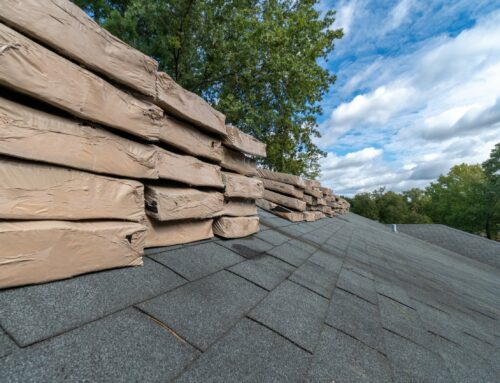

Safety stock, on the other hand, is inventory ordered in addition to cycle stock that helps lumberyards account for uncontrollable variables like excess demand, stock outs, and supplier delays. Many suppliers and dealers hold safety stock for their top clients to mitigate unforeseen issues.

Those most negatively impacted by supply chain issues were, by and large, those implementing just-in-time system inventory planning. That’s not to say a safety stock-focused approach is better than JIT but instead illustrates a need for distributors to be resilient and balanced. Below, learn more about how lumber dealers can strike the right balance between just-in-time and safety stock.

The Importance of Striking the Right Balance

Lumberyards need to find an inventory balance that provides flexibility for unforeseen events, teaming up with a supplier can help them manage the balance.

A supplier that helps balance inventory levels will take the following into account:

- Accelerated e-commerce: Improving the customer user experience and making product information easily accessible has become critical for lumberyards and building material dealers. An up-to-date e-commerce interface should show you live inventory levels and anticipated lead times so you can always plan ahead.

- Contactless delivery: Touch-free delivery shouldn’t come at the expense of transparency. BPI’s Delivery Picture Program provides distributors with photographic proof of delivery and more accurate inventory tracking.

- Streamlined product portfolio: The more products you offer, the more susceptible you may be to disruptions in the supply chain. Working with your primary supplier to refine your product portfolio to focus on quality versus quantity can help lower costs and decrease the likelihood of shortages.

- Bulk buying: Keeping safety stock of critical products protects dealers from unexpected supply chain disruptions. Lumberyards should work with suppliers that have expanded distribution centers to help them determine optimum arrangements for buying in bulk.

It’s important to point out, however, that if you wait to figure out how to handle supply chain disruptions until the disruption has already occurred – it may be too late. Instead, lumber dealers can work with their suppliers to optimize inventory planning and stock levels using the approaches below.

What Is the Solution for Lumberyards?

Preparation

When aiming to achieve a balanced inventory system, preparation is key. Operating models should account for contingencies and risk to ensure lumberyards can be nimble and adaptive. Working with learned data and additional experience, dealers can collaborate with their supplier to continuously improve their systems to reduce waste and optimize margins. Jason Bader states that planning ahead and being transparent with supply challenges brings customers closer.

Supply chain issues brought dealers and suppliers closer to ensure chain visibility and maintain proper stock levels were being anticipated. This close relationship has been crucial throughout a time of uncertain available quantities and a spike in demand. These relationships should be upkept to ensure your yard is maintaining optimal stock levels as consumer demands continue to shift into a new state of normalcy.

Rethink Product Management

With the disruption in the supply chain, the role of purchasing or product manager has changed dramatically, states Jason Bader in his article in Industrial Supply, The Expeditor: A New Role in Purchasing. He recommends “creating a new role primarily to deal with the current supply chain challenges. This new role (expediter) will serve as a backup to all team members. The expediter will focus on filling the gaps created by lead time delays, product scarcity and allocation issues.” In essence, this position will act as the middleman to alleviate any problems that arise from the uncertain supply chain.

Demand throughout the building materials industry has been sporadically shifting throughout the previous 3 years, and this trend does not seem to be changing in the near future. Filling the position of the expeditor will be a crucial personnel move to ensure your yard stays ahead of the curve regarding consumer demands and how they will impact your necessary inventory levels.

Digitalization

“Digitalization is the key enabler to business opportunities in the next 10 years,” according to Gartner experts. They state that leveraging digitalization will support cost reduction and improve customer experience. This conclusion is based on the fact that improvements in the digitalization of your organization will create an easier user experience for your customers. These changes will allow customers to better interact with you online (and urge them to do so more often), cutting down on the associated costs of personnel assisting them.

E-commerce can provide improved visibility into suppliers’ and dealer’s inventories, which can help lumberyards remain resilient in times of uncertainty in the supply chain. Additionally, software for everything from supply chain mapping to real-time inventory counts makes it simple for dealers to map out product lines and know when it’s time to tap into their safety stock.

Collaboration

Over 75% of companies today invest in enhancing their relationships with suppliers. The supplier-dealer collaboration is key to improving resilience and agility by keeping products flowing and ensuring supply chain visibility.

In cases of stock outs or delayed shipments, the lumberyards that maintain cooperative relationships with suppliers are typically favored and receive their products as quickly as possible. This is why it’s essential to partner with a supplier that is trustworthy, puts customers first, and fulfills commitments on time.

For example, BPI partners with building material dealers like Pro Deck Supply to meet customer expectations by providing quality products packaged well for delivery in a reasonable time frame.

Collaborating with a purpose-driven supplier that engages customers and employees in continuous improvement initiatives that help you optimize inventory levels, enhance your product knowledge, and help with marketing efforts to generate business is key to maximizing resiliency and profits.

BPI has been collaborating with lumberyards and building material dealers in the Midwest for over 60 years. Reach out to BPI today to learn how we can best serve your organization.