A home’s siding must not only look good; it has to withstand extreme weather and protect against damage caused by fire, mold, moisture, hail, and pests. With the increase in strong storms and drought conditions, selecting the right siding when building or remodeling a home is more important than ever.

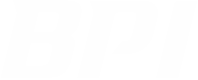

How are Drought Conditions Changing in the Midwest?

Farmers can attest that drought conditions in the Midwest are worsening, and data from the US Drought Monitor backs them up. In January 2020, drought conditions were virtually nonexistent in the region, but five years later, many areas are experiencing drought conditions, increasing the risk of fire. This knowledge should impact your decision on what type of siding (and other building materials) to use.

Siding Options: Comparison of Material Pros and Cons

While there are many choices for a home’s siding depending on the look you want, we’re going to focus on these popular options:

- Fiber cement

- Vinyl

- Composite wood

- Steel

Each of these options comes with pros and cons, so we are going to look at the primary factors to consider when looking at what siding to use on a home.

1. Durability:

Of the four options, steel and fiber cement siding outperform vinyl and composite wood in durability. UV rays, snowstorms, extreme heat, and more can break down siding. The change of seasons degrades materials such as vinyl, which may crack in the cold or soften in the heat. Wood products can expand and contract with changes in moisture and humidity, leaving cracks in the siding and seams. Steel siding and fiber cement products stand strong against extreme weather.

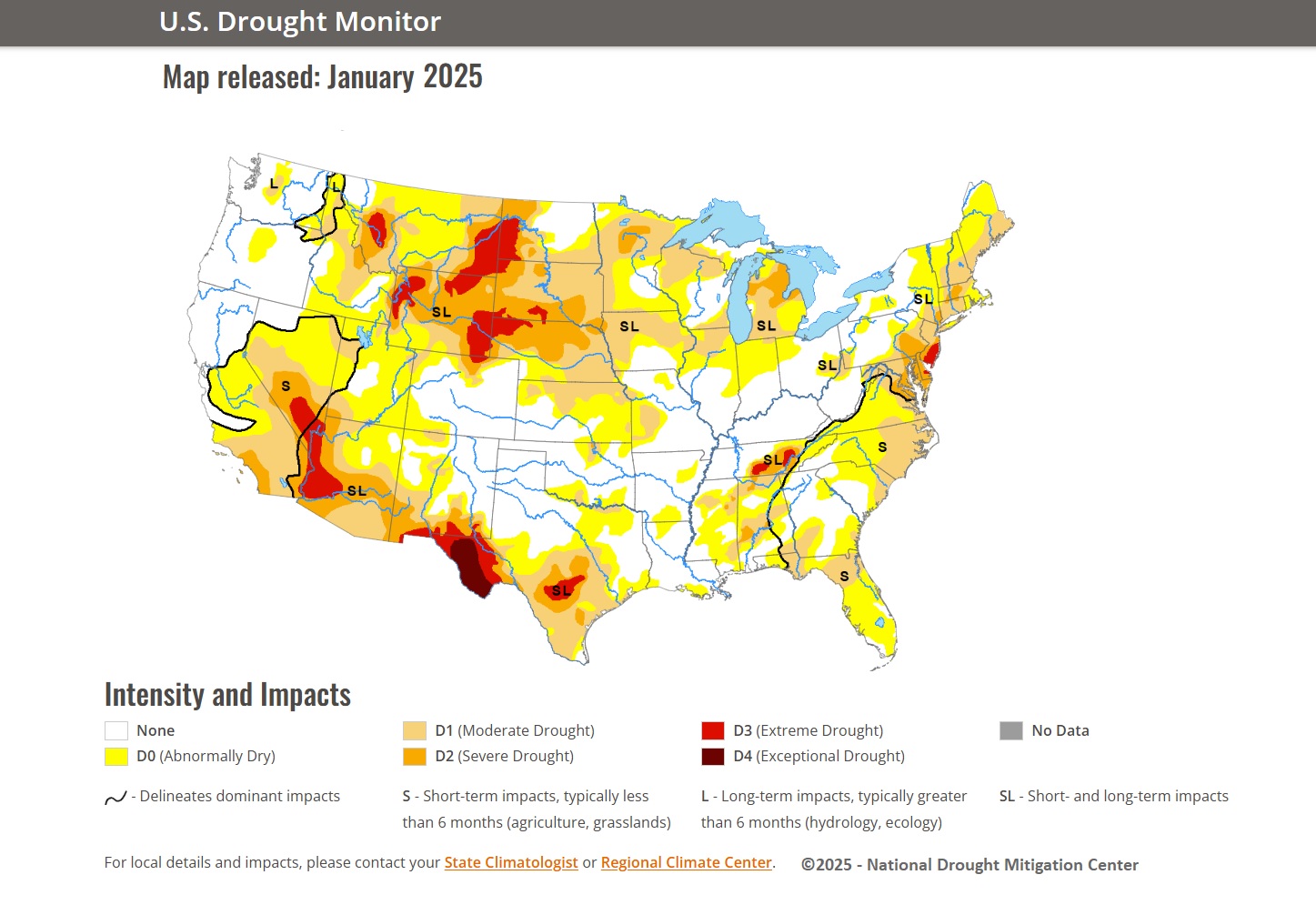

James Hardie fiber cement siding is Engineered for Climate® and was created using the Hardie™ Zone system based on the long-term effects of different climates on siding. This system helps buyers select the right product for their region. HZ5® products are made to resist wet, freezing conditions, and HZ10® products protect homes from heat, humidity, blistering sun, and more.

Quality Edge steel siding has advanced features to withstand heavy winds and extreme weather conditions. Their Vesta Steel Siding won’t melt in the sun or crack in the cold and resists moisture problems that can lead to mold, mildew, and wood rot. With their hot-dip galvanized steel process, Quality Edge steel panels are reinforced with a corrosion barrier that protects them from deteriorating over time. Discover the natural look of wood and the low maintenance and beauty of Vesta steel siding.

2. Resistance to Fire and Heat:

Unlike vinyl and composite wood, fiber cement and steel siding are naturally flame-resistant without any additional chemicals applied to their surfaces. More drought and fire-sensitive areas now require noncombustible siding products as the first line of defense. James Hardie fiber cement and Quality Edge steel siding have a Class A fire rating and will not burn or melt, so they can protect a home in the event of a fire. Vinyl and composite wood don’t have these protections, as fire consumes wood and melts vinyl almost instantly.

Hardie siding will not ignite when exposed to a direct flame, nor will it act as fuel to a fire. And because James Hardie and Quality Edge products are fire-resistant, many insurance companies offer homeowners a discount for using them. Learn how the Panorama House project’s 30 houses with Hardie siding survived the 2021 Marshall Fire that destroyed 1,084 homes in Boulder County, Colorado.

Watch this fire test video of Hardie vs other siding options. You’ll be amazed at the difference in flammability and the safety James Hardie’s fiber cement can offer your family.

>> Fire Test – Hardie® Fiber Cement Siding vs. Vinyl, Composite Wood, & Cedar

Unlike vinyl or composite wood, fiber cement and steel siding won’t warp, deform, or burn from the heat of a gas grill or the reflection of UV rays from your car’s windshield. Fiber cement also prevents heat transfer, which is beneficial in hot and cold climates.

See how Quality Edge siding ranks in this experiment comparing flame resistance on TruCedar Steel Siding, Fiber Cement Siding, and Vinyl Siding.

3. Impact Resistance:

Fiber cement, steel siding, and composite wood resist damage from hail and flying debris better than vinyl siding, which can crack and break from hailstorms. LP Smart Siding has limited warranty coverage for hail damage to its composite wood products. James Hardie products and Quality Edge siding are known for being extremely reliable and durable. James Hardie’s warranty covers its HZ5 and HZ10 products in the case of hail damage. Quality Edge Vesta and TruCedar siding options have the highest class 4 impact rating.

4. Wind Tolerance:

Vinyl siding can rattle in the wind and experience “blow offs” when strong winds lift sections of the siding off a house. Fiber cement siding can withstand over 100 MPH winds. (This home, outfitted with James Hardie siding, was spared from destruction after Hurricane Irma.) James Hardie also develops and tests blind-nail assemblies that independent agencies evaluate and confirm to resist some of the highest code-prescribed wind speeds. Wind tolerance and aesthetics are just two of the factors that continually bring contractors back to Hardie. Quality Edge steel siding is another option that withstands heavy winds. During ASTM Testing in Florida, their steel siding passed each of the six pressure tests and performed so well that the studs blew out before there was any deformation of the siding panels

5. Water Damage:

Water can cause siding to swell, crack, and lose paint, which leads to mold. Exterior solutions by James Hardie are specifically engineered to withstand damage from moisture and will hold their own in rain, sleet or snow. Wood-based siding expands and can buckle or crack when exposed to cycles of precipitation and drying. Vinyl sidings do well in rain or snow but can also crack in extreme temperatures which attracts mold. Quality Edge steel siding is designed not to need a rain screen, with pre-engineered weep holes and a factory edge lap system to continually move water away from the home.

>> Learn How James Hardie and Barricade Products Team Up to Stop Water Damage

6. Pest Resistant:

Many creatures can damage siding. Insects such as termites, wood boring wasps, and beetles can damage composite wood. Woodpeckers can also extensively damage wood siding, leaving it at risk for moisture and other pests to get in. Hardie fiber cement and Quality Edge steel siding offer little appeal to pests, and termites won’t eat it – a big consideration in southern states.

7. Warranty:

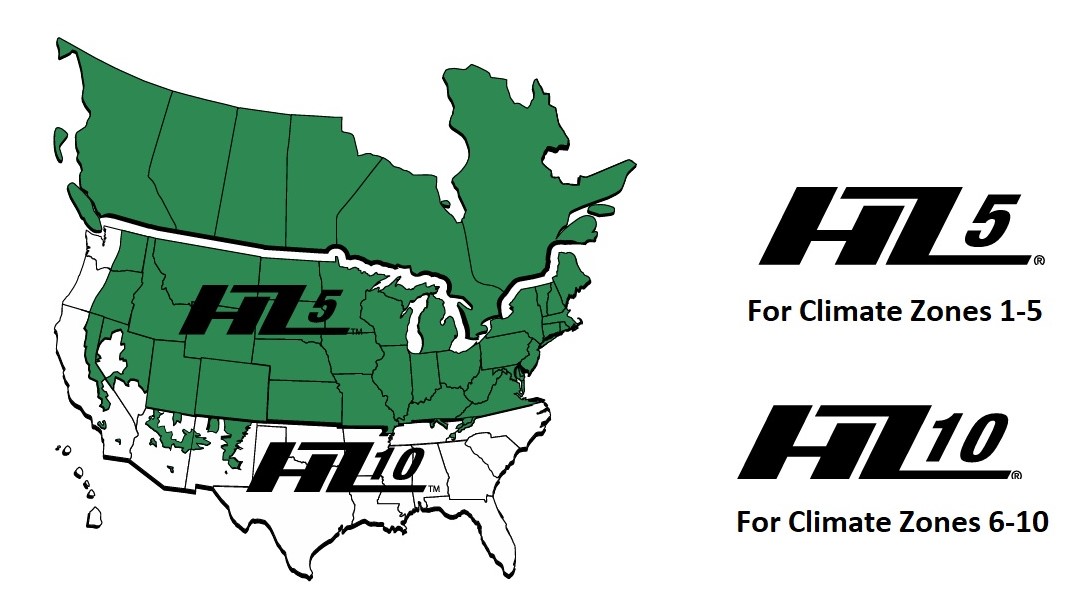

James Hardie has the most comprehensive warranties in the industry. Their siding and trim warranty coverage isn’t prorated, and they stand behind their siding 100% for 30 years and their trim for 15 years. They also include a 15-year, 100% finish warranty on the James Hardie ColorPlus Siding. Quality Edge provides a lifetime warranty on its TruCedar® steel siding and shake sidewall. The warranty covers issues such as cracking, chipping, peeling, chalking, and fading, offering homeowners long-term financial protection. They offer a lifetime limited warranty for its Vesta Steel Siding®, covering manufacturing defects, peeling, flaking, chipping, cracking, color fade, chalking, rust, hail, and abrasion.

On the other hand, LP Smart Side offers a 50-year limited warranty on their composite wood boards, a 5-year limited warranty on their trim, and does not cover finishes. Also, unlike Hardie, LP does not cover hail or termite damage. Vinyl siding manufacturers normally offer a lifetime warranty to the original owner and a prorated warranty to subsequent owners. However, a bad installation by a contractor or previous homeowner could void the product warranty.

8. Resale Value:

A home’s curb appeal plays a significant factor in its resale value and how quickly it sells. According to Remodeling magazine’s annual Cost vs. Value Report from 2024, people who installed fiber cement siding recouped more value (88.5%) than those who installed vinyl siding ( 80.2%). However, those with fiber cement had a much better resale value – around 26.5% higher.

9. Sustainability:

More consumers are concerned about the sustainability of their products, and the manufacturing process for vinyl siding is far from environmentally friendly. The process releases tons of volatile organic compounds (VOCs) into the air, which adds to greenhouse gases. Vinyl siding does not decompose and is difficult to recycle, so if you decide to remodel, the siding will likely go to a landfill. If a home catches fire, vinyl siding melts and releases additional VOCs into the atmosphere.

On the other hand, Hardie fiber cement siding, composed only of cement, sand, and cellulose, is the greenest siding material on the market. It’s very sustainable and the perfect choice for homeowners concerned with the environment. No chemicals are used, and no VOCs are created during the manufacturing process. Fiber cement also breaks down and is recycled much easier than vinyl. And Quality Edge’s innovative and stylish home solutions are made of aluminum and steel, the planet’s most recycled materials. The eco-friendly nature of steel, with its high recyclability and sustainable production, makes it a great choice for environmentally conscious homeowners.

>> Soffit Materials: Comparing Steel, Aluminum, Vinyl, Fiber Cement, and Wood Composite

Choose the Right Siding with BPI

There’s much to consider when choosing siding, from durability to fire resistance to resale value. Whichever you choose, one of BPI’s authorized dealers can help you make the best choice for your multi-home build or your personal home.

Contact our expert team or an authorized BPI dealer near you to learn more about siding and trim options, including James Hardie and Quality Edge.