How the total cost of ownership impacts lumberyard profits is often misunderstood. This paradox arises when too much emphasis is placed on securing the lowest possible price, which can, in fact, lead to higher costs over time. For lumberyards aiming to maximize profits, understanding the total cost of ownership (TCO) is critical for long-term success.

After all, it’s natural to fixate on the sticker price. Doing so, however, may lead you to overlook or forget about the acquisition cost, which can easily result in a higher overall cost per item.

For example, when a lumber business deals with dozens or sometimes hundreds of vendors, communication and documentation become burdensome and daunting. On the other hand, partnering with a single distributor like BPI instead streamlines the buying process – saving you time, labor, and energy — all of which can then be redirected toward accomplishing other goals.

This is because customer-focused, two-step distributors like BPI will resolve purchasing problems before they reach your purchasing team, saving you the costs of valuable resources such as the time and focus of talented team members.

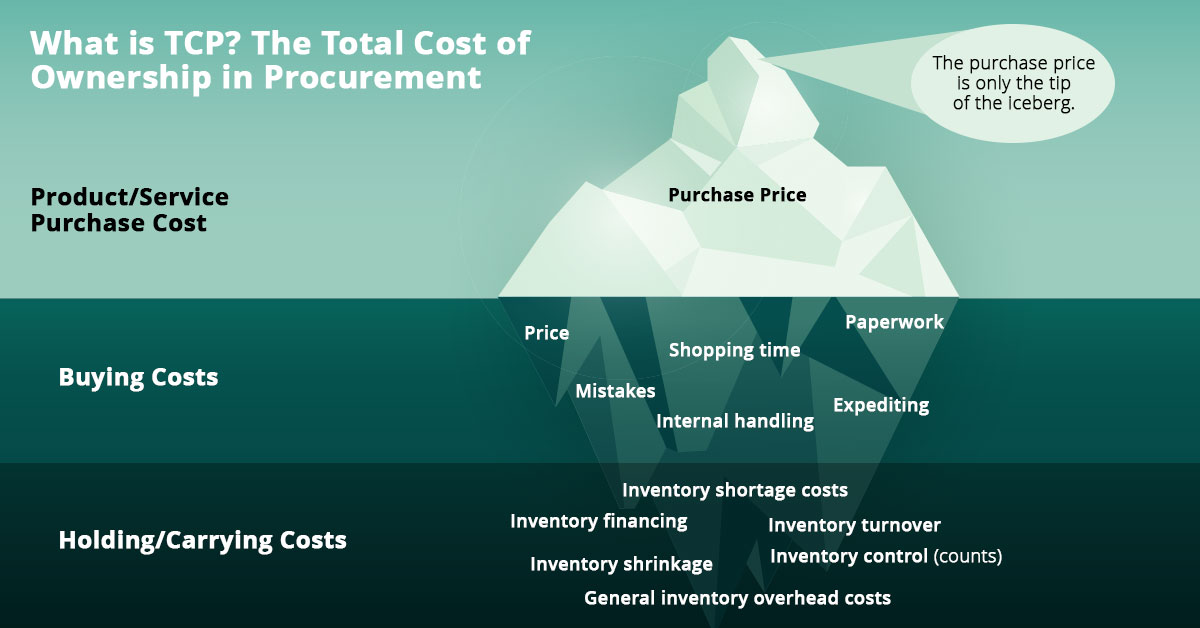

Understanding this paradox requires understanding how various costs that are part of the buying process affect what’s called the total cost of procurement (TCP).

>> Learn the benefits of using a two-step distributor for lumber & building material dealers

Total Cost of Ownership and Its Impact on Procurement

What is the definition of the total cost of ownership (TCO)? The TCO includes the purchase price of a particular asset plus operating costs over the asset’s life span. However, since lumberyards and distributors typically don’t use the assets they’re selling, we break it down to the total cost of procurement (TCP). Understanding how the total cost of ownership impacts lumberyard profits helps clarify why focusing on the TCO is critical for cost management.

Understanding how the total cost of ownership impacts lumberyard profits requires factoring in the total cost of procurement (TCP). The TCP includes not only the purchase price of an item but also the time, money, and effort your organization spends to find, buy, handle, and store it. These hidden procurement costs can often go unnoticed, yet they significantly affect your bottom line. What may initially seem like a great deal can end up costing much more due to higher procurement expenses, directly influencing how the total cost of ownership impacts your lumberyard’s profitability.

Elements of TCP for Purchasing

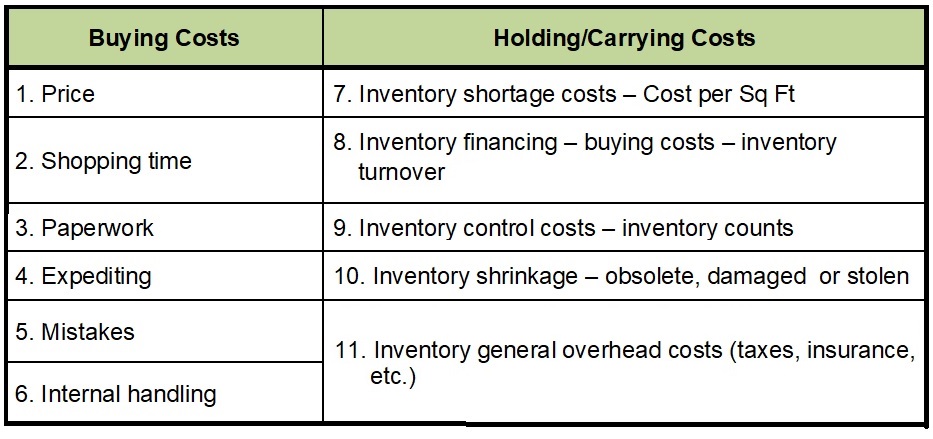

In the supply chain, eleven elements make up the total cost of procurement. In this article, we’ll look at the costs associated with buying (items 1-6 below). We’ll take a look at the holding / carrying costs in upcoming posts.

Hidden Purchasing Factors That Increase the Total Cost of Ownership

Let’s see how the first six factors impact your procurement cost.

1. Price. It’s important to know the true price your organization pays involves more than just the price tag for each item. For example, if you use a low-bid procurement strategy to buy a high quantity at once, you have to consider how and where to store all of the extra material and factor in your holding and carrying costs. Working with a two-step distributor like BPI can alleviate the need to store the excess inventory to gain the pricing discount.

Also, there’s truth in the old saying that you get what you pay for. Obtaining the lowest possible purchase price can easily mean you wind up getting shipped shoddy, damaged, or substandard materials. Bidding in procurement policies can incur additional costs through replacing the items or fixing problems that result from their unsuitability.

2. Shopping Time. Getting a lower price often means spending more time on comparison shopping and identifying suppliers, getting supplier-buyer approval, and setting up new suppliers in your system. All of that bargain hunting eats up valuable time that might actually cost more than you save on the purchase price.

When you’re investing extra time trying to find the lowest possible price, you’re adding the cost of your staff’s time and labor into the equation — at an average of $68 per hour, according to one analysis based on the Industrial Distribution 2024 Salary Report. Which means that just one extra hour per day spent on purchasing tasks can wind up costing $340 per week, adding up to $17,000 per year.

In fact, one of the most common complaints of mid-level managers, such as purchasers, in the ID survey was that their workload has nearly doubled. When talented team members get overloaded with low-level tasks, it negatively impacts their productivity. It leads to burnout, job dissatisfaction, and eventually, the possible loss of valuable employees as they look for less stressful working situations.

3. Paperwork. Buying different materials based on the lowest price for each item usually means creating multiple POs for multiple vendors. When you factor in the average cost of processing a PO — which itself comprises a series of steps including requisition, approval, order placement, delivery confirmation and invoice matching – costs are driven even higher. In fact, the American Productivity and Quality Center’s 2024 study found the median cost per purchase order to be approximately $100.

4. Expediting Purchase Orders. Another hidden expense is the time and labor spent on ensuring your product arrives as scheduled and the cost of troubleshooting when things go wrong. As Bruce Merrifield (a strategic advisor on distribution channels) notes, the suppliers that offer the lowest prices usually tend to have the worst service — a “no-frills” tradeoff that can come back to bite you when things go wrong.

Expediting purchase orders from vendors who renege on promise dates often will result in not only more work for your purchasing team, but the wait times caused can create higher construction costs for your builders and contractors, resulting in lost future business for your dealership. The more POs and vendors you deal with, the more this problem multiplies.

5. Mistakes. In addition to delays, consider the impact of other types of errors. Receiving the wrong items or having purchase order mistakes, such as incorrect pricing or other issues, results in even more costs associated with processing the return and replacement of those items or resolving incorrect documentation.

6. Internal Handling. Every PO winds up generating internal handling. And the bigger your company is, the more internal handoffs will likely be generated. When materials arrive at the dock, they must be unloaded, broken down, and then sent to wherever they’ll be put away and stored. This process demands significant time and labor investment.

It’s important to note that all the above costs are incurred just in purchasing and receiving the materials. The list doesn’t factor in the costs of storing and managing the items once they become part of your inventory. We’ll go into those costs in a future post.

How BPI’s Services Can Help Reduce Your Total Cost of Ownership and Procurement

Fortunately, there’s an easy way to get a handle on the situation. Let’s look at how BPI can help you rein in each of the buying costs mentioned above and understand how the total cost of ownership impacts lumberyard profits.

1. Better Pricing. BPI buys and stores items in bulk, which allows us to pass better pricing along to you and to supply just what you need – when you need it. BPI purchases a diverse range of product lines, offering you an increased selection of options and price points to choose from.

2. Reduced Shopping Time. Because many distributors prioritize allocating inventory to their steady customers – those whose needs they know and can plan for, buying from multiple distributors can easily result in extended shopping time and costly backorders. BPI customers have a trusted partnership with our team that results in our better understanding of their needs while helping them reclaim most of the time invested in identifying and dealing with multiple suppliers and vendors.

Taking advantage of one-stop shopping with BPI to place consolidated orders instead of frequent smaller orders not only saves purchasing time — it allows BPI to pass along even better pricing. This also reduces your yard staff’s time to unload trucks and move inventory, reducing the opportunity for errors in the put-away process.

3. Streamlining Paperwork. The additional POs, invoices, and other documentation generated from dealing with multiple suppliers get consolidated into a single manageable stream when you work closely with BPI. The consistency and predictability created by having a solid customer-supplier relationship with BPI helps eliminate costly mistakes and misunderstandings. As BPI sales reps get to know your needs, they can look out for your lumberyard to ensure you get exactly what you need, on time, even if it’s drop-shipped straight from the manufacturer to your customer’s job site.

4. Assisted Expediting. Our customers have an established two-way channel of communication with our reps, who make sure the delivery of supplies is timely and accurate. BPI helps with planning and problem-solving to eliminate logistical delays and snafus. We coordinate effectively with lumberyards that have a late cutoff for delivery or pick up to allow quick response and delivery.

5. Preventing Mistakes. As one of its initiatives to reduce mistakes, BPI makes use of Continuous Improvement Practices, a multistep process that improves quality, efficiency, and consistency — and minimizes paperwork and expediting headaches for customers. Additionally, BPI sends out invoices one day after shipping in order to help make sure mistakes get caught before billing goes out, which also helps eliminate paperwork for the lumberyard.

6. Improved Handling. BPI places a high priority on smooth handling with less shrinkage, with approaches that include Advanced Shipping Notices and a Delivery Picture Program in which BPI provides a photo of each delivery made to a dealership so your team can see all the critical data points: when each shipment arrived, what it included, where it was delivered, and the condition of the shipment. BPI also provides an Enhanced Packaging Process, especially for millwork and decking, to minimize damage in transit. BPI has improved how their doors, siding, and decking are palletized in order to minimize damage and make products easier to handle when received.

How BPI Job Packs Can Optimize Efficiency and Lower the Total Cost of Ownership

Another effective way that BPI helps lumberyards keep their inventory on track and lower their total cost of procurement is with job-related bundling, known as BPI Job Packs. This strategic approach maximizes efficiency by tagging packs by job and job site. It keeps builder projects on schedule as it enhances visibility and traceability for each order — saving both time and money.

BPI Job Packs are designed to minimize errors on orders that include multiple items for related tasks — things like roofing materials, doors and trim, cabinets, decking, and more. By reducing errors and improving organization, these packs contribute significantly to lowering the total cost of procurement for your business.

For example, if you place an order for 80 doors and related items for your builder’s job site, choosing a job pack means that all the products in your order will be tagged and bundled to arrive at the same time in a single shipment, instead of spread out into scattered deliveries. This simplified process delivers significant benefits in terms of organization, convenience, accuracy, and speed.

Doing business with a two-step distributor like BPI, which understands the concerns of your lumberyard and your customers, provides a lower total cost of procurement and trust that your products will be delivered when you need them and where you need them.

Get in touch with us to learn more about how BPI can help your lumber dealership reduce costs and increase your margins.

Builders and contractors: Lower your total cost of procurement – find a BPI dealer near you and ensure your builds have quality products delivered on schedule.