Making positive changes in your organization is about more than fancy methodologies and technology — it’s about the people: both your employees and your customers. BPI began implementing continuous improvement initiatives to boost customer service in 2021 – learn from BPI’s key takeaways on instilling trust among your team, putting your customers first, and making continuous improvements.

Why Did BPI Work to Improve Their Business Operations?

BPI recognized that there were outdated internal processes that needed updating. Close examination of systems revealed outdated practices that had to be revamped if BPI was going to continue meeting customer needs. Following an internal review, more dynamic and fluid processes were introduced, fostering continuous improvement for BPI. In time, these shifts, not without challenge, created positive change for the company. Below, learn more about the steps BPI took, and the complications they overcame, to bring better service to their customers.

BPI’s First Step Toward More Efficient Processes

When BPI began its journey toward process improvement, the company first acknowledged that every branch had different operating procedures, and a need for standardization. In many cases, BPI relied solely on employee knowledge to carry out day-to-day operations. While it’s true that team members must understand the ins and outs of their systems to be successful, knowledge alone is not scalable, especially when the organization has more than one location. Because of this, BPI aimed to make business operations consistent throughout the organization.

How BPI Improved Their Primary and Support Processes

BPI decided that to optimally improve their processes, they would need to invest heavily in their employees. With internal systems differing from location to location, employee buy-in was necessary to shift operations to a one size fits all model that could be replicated between locations.

Once BPI gained employees’ trust and willingness to change, the company shifted its focus toward how system improvements could benefit their customers. The company understood that delivering value to their customers through operational excellence would require a clear, customer-centric purpose.

Purpose and Value Mapping

For BPI, the company’s purpose was to provide the best possible service and products to customers when they need them. This required continuous discussion and evaluation on how each of their processes added value to the customer. If a process offered no value, it was eliminated; if it delivered high value, it was reinforced.

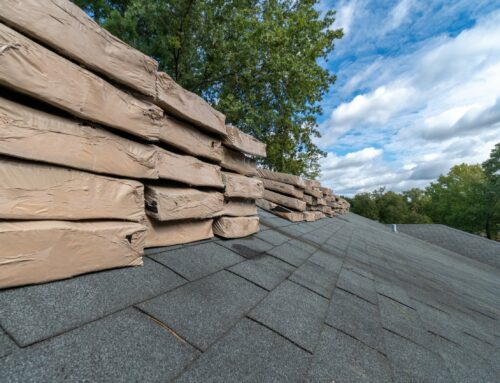

For example, the company identified decking as a major problem area. Too much product was incurring damage during delivery. To address this problem, BPI mapped the value stream by working backward. This inverse path included the following basic steps:

- Items are received by the lumberyard or dealer

- Items move through BPI’s delivery, staging, and picking systems

- Items are stored at BPI and stock is replenished in a particular way

- Items are unloaded from suppliers’ trucks at BPI

- Items are delivered to BPI from suppliers

Each step of the process was analyzed for ways to improve quality, efficiency, and consistency. Working backward revealed that one of the main sources of damage was the result of poor packaging. Patrick Dinneen, BPI’s Sioux Falls Market Manager, recalls, “we implemented a new packaging process for decking. When we break a bundle, every piece of decking has to be wrapped, no exceptions. We also started labeling everything so that when the customer receives it, they know exactly what the product is and where it should go in their lumberyard.” This greatly reduced the amount of damaged product BPI’s customers received and also lowered the number of credits being issued. It was truly a win-win scenario!

While poor packaging was one of the biggest pain points BPI’s customers were experiencing, working backward through the value stream also outlined how disorganization in their warehouses was causing shipping delays.

Warehouse Organization

BPI also reset its warehouse processes and organization, allowing for better flow, to guarantee every order is picked and shipped the day the customer needs it. Warehouses were divided up into staging zones, much like UPS or FedEx but on a smaller scale. This change enabled BPI to get products ready to load on its trucks much faster and ensured greater order accuracy.

Encouraged by the success of the above-mentioned continual improvement initiatives, BPI looked for ways to foster more ideas that optimized efficiency. To create new ideas, they began performing routine Gemba walkthroughs of their warehouses.

Continued Improvement

“Gemba walks are a way to observe where the work is performed and where value is created before taking action. Actively soliciting input from warehouse employees on a consistent basis ensures new problems are ironed out quickly and ways to improve the process are noted and implemented. They are the first to take note of these changes, which is why Gemba walks are so important,” states Dinneen.

For example, one of BPI’s manufacturers changed the way they package their products, resulting in increased product damage. BPI, in turn, responded by changing its processes for packing and delivery. A few days after the new process was rolled out, they came back and reassessed its effectiveness (part of Lean’s Plan-Do-Check-Act or “PDCA” cycle). The new packaging initiative resulted in drastically less product damage occurring throughout the shipping process.

Another improvement made by BPI involved RMA’s. The company noticed the waste and customer dissatisfaction stemming from a lengthy return process. BPI then chose to prioritize returns immediately to provide a competitive advantage and a better customer experience. Instituting this change cut back on the time it took to process RMAs, and increased customer satisfaction with their returns.

While the idea of continual change may seem overwhelming, these changes are what allow companies to thrive through rapid growth and other challenges. Below, see some of the ways you can implement continuous improvement initiatives in your business.

9 Steps to Implement Continuous Improvement at Your Lumberyard

- Put purpose first: Before identifying value, identify the purpose for change, which should be to provide better service for your customers. Then, you can connect with your customers to help determine value and ways to improve process flow.

- Gain employees’ trust: Acknowledge that you must change behaviors before you can change anything else. Gain buy-in and trust from employees and make them part of the process.

- Map value streams: Mapping your value streams will help you prioritize solving customers’ problems first as well as reduce waste. Start with delivery to the customer and work backwards all the way through packaging, picking, warehousing, order taking, and vendor order placement.

- Problem-solve: Utilize structured problem-solving techniques and focus on solving the right problem; ask why five times to get to root causes; make sure that the process always has focus on the strategic purpose – if it doesn’t, then the solution will not provide value to the customer.

- Document everything: Keep track of all new or updated processes. Institutional knowledge from employees is great but scaling innovative processes across a company requires everyone to be on the same page. Documentation is also crucial for efficient cross-training and quickly teaching new employees.

- Iron out the kinks: Consider everything that negatively affects your contractors and end users then work to change those processes for the better. Encourage departments to work with each other to get the best end-result for your customers. Collaborate with your suppliers to work out packaging, labeling, product availability, and other issues.

- Walk through your facility: Get out and walk through your facility to observe what’s really going on. Make sure that processes have an efficient flow so you can get products out to customers as quickly and accurately as possible.

- Create a continuous improvement culture: This isn’t a one-time change. Constantly evaluate your processes and make adjustments if something isn’t working (Plan-Do-Check-Act). A few days after you roll out a change, get feedback from employees and customers. Then, review again in a month. And be prepared to change the process again.

- Encourage experimentation: Encourage and appreciate input from employees when it comes to changing or modifying processes. Train new employees to always think of how their job impacts the end user. Develop champions who will pass on the principles and systems at your organization.

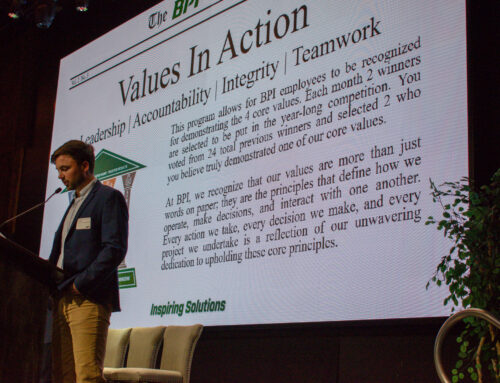

Bonus Tip: Build Continuous Improvement Leaders in Your Organization

In addition to employee buy-in and encouragement, it’s essential to develop a talent pipeline for future leaders in your organization. Encourage every employee to practice leadership traits. Everyone has valuable insight to offer. Developing leaders will help make the difference between a successful company and an unsuccessful one.

In time, these up-and-coming leaders will champion your continuous improvement and communication systems to new employees – ultimately, creating an ecosystem of efficiency, reduced waste, and loyal customers.

We here at BPI are implementing continuous improvement initiatives to better serve you. If you have ideas on ways we can better serve you, please reach out to one of our sales representatives. We appreciate your business and look forward to continuing to partner with you.