Is economic instability affecting your lumber dealership’s profits? A review of your operations can help you uncover ways your company can tighten its belt just a notch or two by reducing cost and retaining employees while still turning a profit.

We’ve been focusing on operational costs ourselves, as have several of our customers. Here are 9 solutions that could help you reduce your expenses, as well.

Solution #1: Decrease Your Carrying Costs

Your carrying cost is one of the most important metrics for you to consider when reducing overhead. Carrying costs, or what it costs you to hold inventory, typically range from 20% to 30% of your inventory value. That stagnant inventory on your shelf is cash you can’t access to invest in other areas of your business.

inventory value. That stagnant inventory on your shelf is cash you can’t access to invest in other areas of your business.

So here are some ways you can immediately reduce your carrying costs.

Find the Right Reorder Point

The ideal reorder point for products avoids shortages but keeps you from having too much extra inventory. Beyond the loss of immediate sales, inventory shortages could lose you clients and potentially result in a bad reputation that you can’t meet customer needs.

There are a couple of ways to find the right reorder point:

- Speak with your customers about their ongoing needs and keep only that much stock on hand at regular intervals.

- Use demand forecasting. By looking at previous months and years, you can forecast the demand for products during each season or month and order stock based on that data.

Remove Obsolete Stock

Obsolete stock takes up space that you could use for more current products. Don’t store stock that you won’t sell. You just might need to think differently about how to move it.

For example, you can bundle your more obsolete stock with current products, selling the obsolete stock for a fair discount. Or you could use a service to sell obsolete stock at auction. This is an excellent way to obtain the full residual value of the products you’d like to unload.

Implement a Lean Warehouse Strategy

Running a lean warehouse ensures that you keep less stock on site but always have what you need where you need it when you need it. We have conducted lean warehouse implementation and have identified strategies your peers are implementing. Our sales reps have been in dozens of dealerships and understand your business needs in depth. They’ll be happy to talk about strategies to make your operations leaner and meaner.

Reduce Dwell Time

The more time someone spends idle, the less profitable your company will be. So how can you keep your employees more productive during their shifts? Get them more engaged in your operations. And if you’re trying to run a lean warehouse, this is even more critical.

Being a part of the process of implementing Lean initiatives helps create buy-in for all employees and can reveal problems that management might not be aware of. In other words, ask your employees about their pain points on the warehouse floor. Dwell time isn’t necessarily the result of someone being lazy; it could be the result of inefficient processes.

For example, how much time elapses between a truck arriving to pick up a delivery and being loaded? What’s causing that delay? Is it a lack of a clear staging area at the loading dock for orders? Is it poor communication between the warehouse and the dispatcher about arrival time?

Odds are every one of your employees has an idea on how to improve the workflow in your warehouse. Get them engaged in solving the problem.

Improve Retention

Engagement has a secondary benefit; it helps improve retention, which is a great way to reduce labor costs as well. A study done by the Washington Center for Equitable Growth estimates that, on average, turnover costs represent 39.6 percent of a position’s annual wage. This is due to the amount of time and money spent finding, hiring, and training the new employee.

Engagement has a secondary benefit; it helps improve retention, which is a great way to reduce labor costs as well. A study done by the Washington Center for Equitable Growth estimates that, on average, turnover costs represent 39.6 percent of a position’s annual wage. This is due to the amount of time and money spent finding, hiring, and training the new employee.

Engagement provides a sense of ownership in overall results. According to Gallup, companies with high employee engagement ratings are 22% more profitable than their peers.

Another way to improve retention is to offer cross-training and upskilling. Giving employees opportunities to improve their skills can help them feel like they have a future with your company. This training also helps them be more productive in their work with you, so it’s a win-win situation for everyone involved.

Solution #2: Join an Industry Trade Association

One of the best resources for tips on how to streamline your resources is others in the industry. Trade associations offer you a way to connect and exchange ideas with others facing the same struggles as you. Many industry trade associations also offer educational resources for all levels:

- North American Wholesale Lumber Association – webinars, technical guides, etc.

- National Lumber and Building Material Dealers Association – webinars on OSHA regulations, training requirements, and other federal regulations and training materials on forklift and delivery & fleet safety

Some trade associations provide members with direct ways to save money, too. By pooling the collective purchasing power, members can negotiate highly competitive rates on a host of programs and services.

For example, the Mountain States Lumber & Building Material Dealers Association offers its members benefits such as business insurance, credit card and payroll processing, and more.

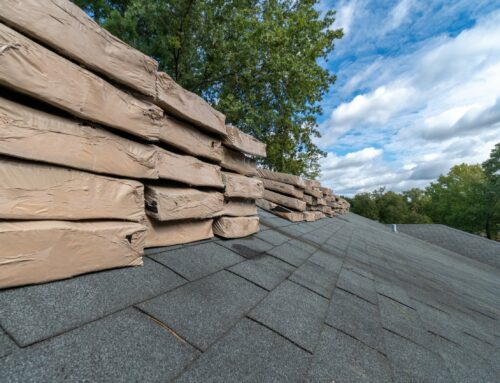

Solution #3: Safeguard Your Inventory

Most warehouses operate knowing that there will be some inventory loss along the way. This could be due to theft, equipment malfunction, or even items damaged in transit. In the U.S., inventory shrinkage accounts for upwards of $61 billion annually.

The easiest way to reduce your inventory loss is to focus on what you can control, including how you store and deliver products to your customers. Figure out where and how damage occurs and find ways to prevent it.

For example, enhanced packaging, like we offer here at BPI, can help prevent costly damage during transit or on a jobsite by adding an extra layer of protection during critical times. Reconfiguring storage racks can also help.

What about when the product leaves your site? We all know the stories of goods leaving the warehouse in great condition only to have a customer reaching out about damage. It can devolve quickly into a he said/he said, taking time and effort to correct the issue.

Another simple solution could help protect you in this situation: a proof of delivery picture program. We track your products with date stamped images right up to delivery at your facility or at the job site. It also creates an additional accountability step along the way. Proof of delivery will help you maintain an accurate inventory, saving lost time and effort to look for missing products and also helps reduce and mitigate theft.

Solution #4: Implement Reductions in Energy Costs

Warehouses tend to be big spaces that require a lot of energy to operate smoothly. Asking your employees to shut off the lights when they’re not in a room isn’t enough to have a significant impact on your bottom line, but there are a few relatively simple ways you can reduce the operating cost of energy. For example, improve your building insulation to improve energy efficiency, use automatic lighting systems, reduce water usage and automate thermostats.

Solution #5: Reduce Delivery Costs

Sky-high gas prices and a shortage of qualified and available drivers keep pushing the costs of delivery higher and higher. But eliminating the service isn’t an option for lumber dealers. However, you can implement new strategies to offset your transportation costs.

Share the Cost

Charging customers more for the same service is never ideal, but sometimes it’s necessary. Your clients are seeing the same prices at the fuel pump that you see, so they’ll likely understand the need for a surcharge or an increase in the delivery fee – if you communicate the reasons clearly.

Another route is to raise prices across the board, incorporating a fuel surcharge into the product cost overall. There are drawbacks to this approach, however. You’ll still need to abide by prices for customers with contracts until the provisions of that agreement allow for a price change, meaning you may not be able to recoup the rising costs as quickly as a fuel surcharge would allow.

Outsource Deliveries

Let’s face it. Managing a delivery fleet is expensive. Beyond the cost of fuel and drivers, there’s maintenance, insurance and storage.

It’s also complicated. Customer expectations around delivery have changed as they’ve become accustomed in their personal lives to two-day guarantees and scheduled times. In addition, you have to understand efficient routing and traffic patterns, otherwise you’re just upping your costs unnecessarily.

Partnering with a logistics or delivery company to take on some or all of that load can help you streamline your operations and reduce your overall costs. There are several companies that specialize in doing this and only this, so they can do it far more efficiently than you can.

Solution #6: Find the Right Technology Tools for Your Business

It’s easy to get overwhelmed when talking about technology, but investments in the right applications – such as the automation tools mentioned above – can have a dramatic effect on your long-term profitability. Having essential information at your fingertips can reduce man-hours, improve accuracy, increase visibility, give you more control over operations and increase profitability.

When looking at platforms, a lot of different acronyms will be thrown at you, and a lot of them will be able to help you achieve many of the goals on this list. Two of the most common will be an enterprise resource planning (ERP) system and a warehouse management system (WMS).

ERP systems tend to have more applications within your operations than WMS options, such as finance and human resource tools, but that doesn’t mean ERP is the right tool for you. To be able to do demand forecasting, purchasing, sophisticated inventory management and track KPIs, an ERP is the way to go. However, if you won’t use the additional tools and don’t foresee needing them in the future, it may not be worth the additional expense and time to implement.

Solution #7: Keep Track of Your KPIs

How do you know if your improvements are paying off? You measure the results though key performance indicators (KPIs). KPIs serve as a report card for your warehouse and provide tangible metrics for different areas of your operations.

KPIs can measure anything you want them to, but you should focus on concrete measurements and be relevant to your specific operations, such as order-picking accuracy. The goal should be to identify areas where you can improve, either via process improvement or better training.

Below we lay out some suggested areas for distributors to look at when setting KPIs.

Inventory

- Backorder rates

- Carrying cost

- Inventory accuracy

- Inventory-to-sales ratio

- Shrinkage/inventory loss

Receiving

- Cost of receiving per line

- Cycle time

- Receiving efficiency

Putaway

- Accuracy rate

- Putaway cost per line

- Putaway cycle time

Order Management

- Picking accuracy

- Fulfillment accuracy rate

- On-time shipping rate

- Cost per order

- Rate of returns

Safety

- Accidents per year

- Time since last accident

Don’t just rely on this list, however. Figure out what you want to measure and how to best approach it, and even better, automate it.

Solution #8: Take Advantage of Cross-Docking

Much like discussed above, under just-in-time ordering, cross-docking removes or reduces storage costs by reducing the time product spends on your warehouse shelves. Products are removed from delivery vehicles such as trucks or railroad cars, sorted, and immediately loaded onto outbound vehicles for delivery.

This process also can increase delivery efficiency, meaning customers receive orders faster. But that’s only a benefit if you maintain accuracy and quality in the process. Cross-docking requires your distribution center to have an excellent organizational system to keep track of all incoming and outgoing shipments.

Technology can play a critical role in achieving this level of organization. At BPI, for example, we know how advantageous cross-docking can be for our customers, so our warehouse management system is optimized for this type of use.

Solution #9: Talk to The Experts

You have a lot of opportunities and decisions to make to reduce overall costs in your warehouse. It can be hard to make the best choices for you and implement them efficiently.

This is why talking to experts in lumberyard and warehouse efficiency, like our staff at BPI, can be an intelligent choice.

As you can tell, we are very passionate about strategies for a highly organized lumberyard with low overhead cost. With our expertise, you can reduce your carrying costs and increase overall warehouse efficiency.

If increasing profits while reducing costs sounds like the solution you need, contact us to see how our solutions can help you.